Capabilities

CNC Turning

The versatility of our CNC Lathe machines gives us the capability to perform various tasks with precision and efficiency. Our turning operations span through a wide range of capabilities including

- cylindrical turning

- taper turning

- thread cutting

- drilling

- boring

- groove & parting

- contour and profiling

- bar feeding

Our CNC turning machines can work with a wide range of materials, including metals such as aluminum, steel, brass, copper, and plastic. The material from a rotating workpiece to create cylindrical shapes, such as shafts, rods, and discs.

CNC Turning Equipment

Hyundai, WIA E 160A CNC LATHE

- Maximum Diameter – 8”

- Maximum Turning Length – 11”

Hyundai, HIT-8G

- Maximum Diameter – 1-1/2”

- Maximum Turning Length – 4”

Yang CNC Lathe, ML25A

- Maximum Turning Diameter – 11”

- Maximum Turning Length – 15”

Yang CNC Lathe, ML25

- Maximum Turning Diameter – 11”

- Maximum Turning Length – 15”

CNC Milling

CNC milling machines can achieve high levels of accuracy, ensuring production is met with tight tolerances and specifications allowing for highly accurate and repeatable production, handling various materials such as metal, aluminum, carbon fibre, plastic, and rubber. Our milling machine service offers a comprehensive range of capabilities including

- 3-Axis, 4-Axis, and 5-Axis machining service

- face milling

- peripheral milling

- drilling

- engraving

- pocket milling

- thread milling

- gear cutting

Whether you need simple geometric shapes or intricate designs with multiple angles, our versatile machinery allows us to deliver precision and efficiency in every job.

CNC Milling Equipment

Hyundai, KF 5600C

- X Axis – 40.5”

- Y Axis – 20”

- Z Axis – 20.5

Kitamura, My Center 3XD

- X Axis 30”

- Y Axis 20”

- Z Axis 20”

Matsuura, RA-IVF

- X Axis – 40”

- Y Axis – 20”

- Z Axis – 20”

Matsuura, MC510V

- X Axis – 20”

- Y Axis – 14”

- Z Axis – 18.1”

Bridgeport, V1000

- X Axis – 40”

- Y Axis – 24”

- Z Axis – 24”

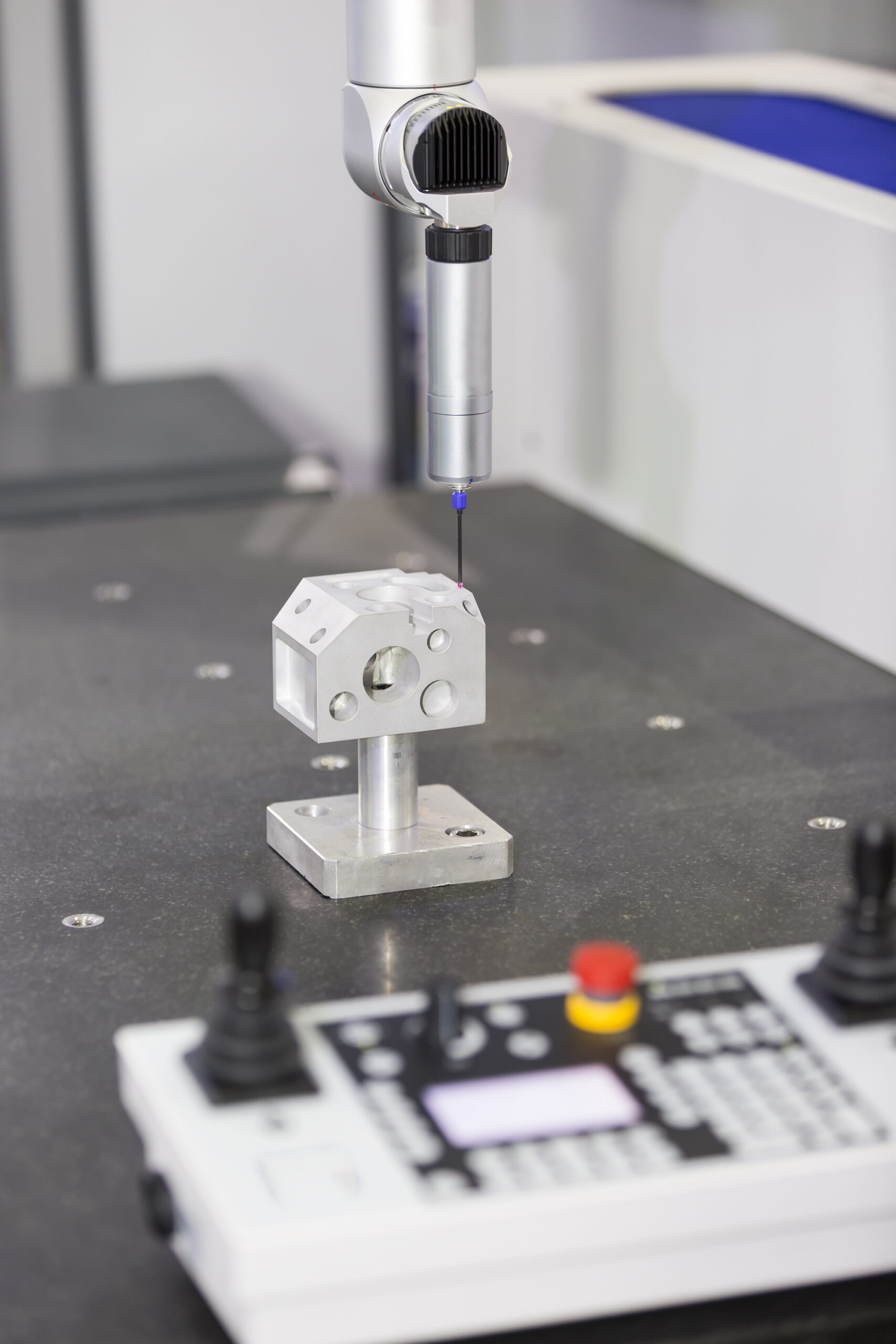

Quality Control

Our CNC machining company is proud to be ISO 9001 compliant, underscoring our commitment to stringent quality control measures and continuous improvement and ensuring to adhere to international standards for quality management, guaranteeing consistency, reliability, and superior quality in every product we manufacture. Some machines we utilize for standards of precision and quality include

- CMM’s

- Calipers

- Micrometers

- Digital height

- Gauges

- Laser scanners